Creating your desired polished concrete floor requires planning and some careful choices.

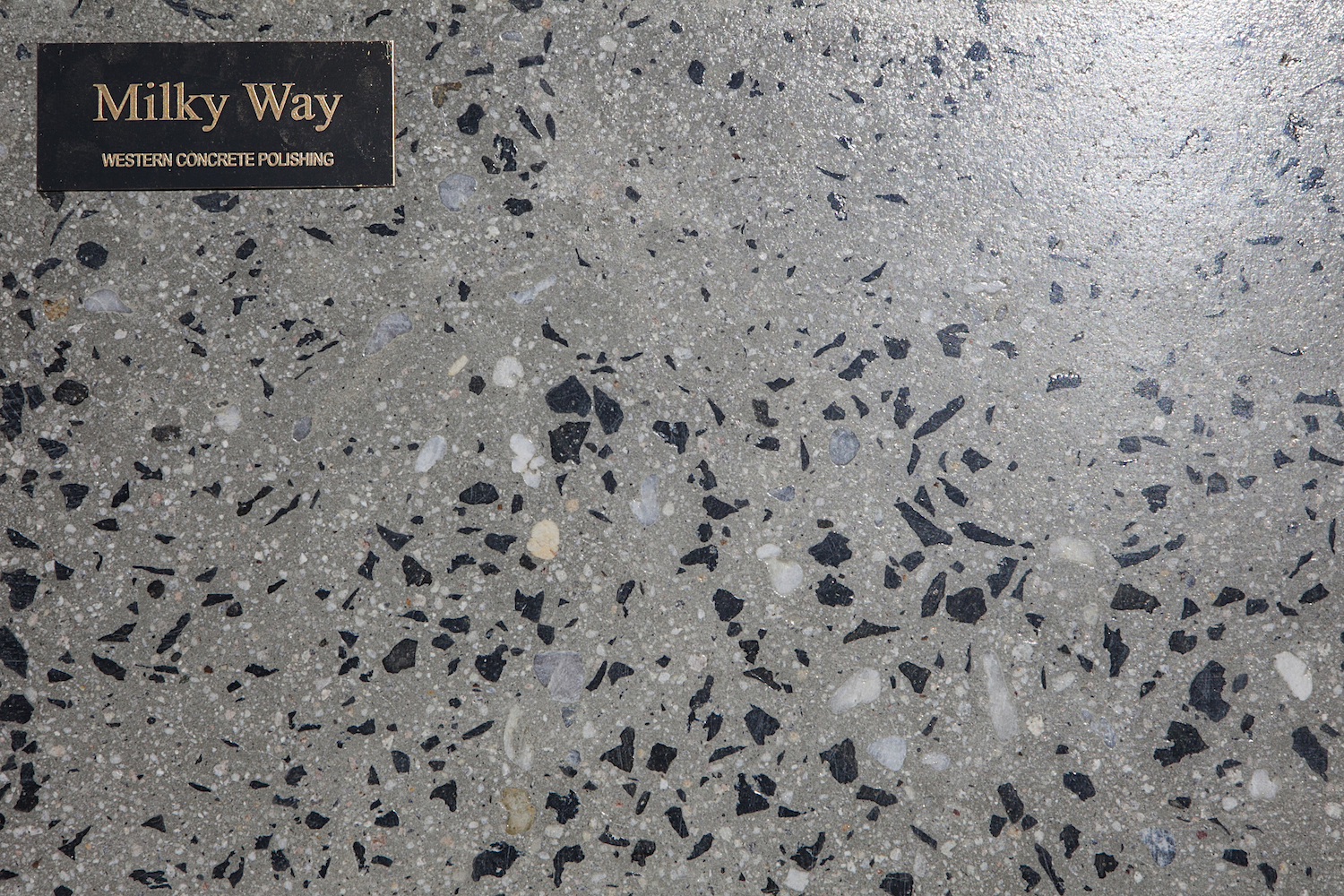

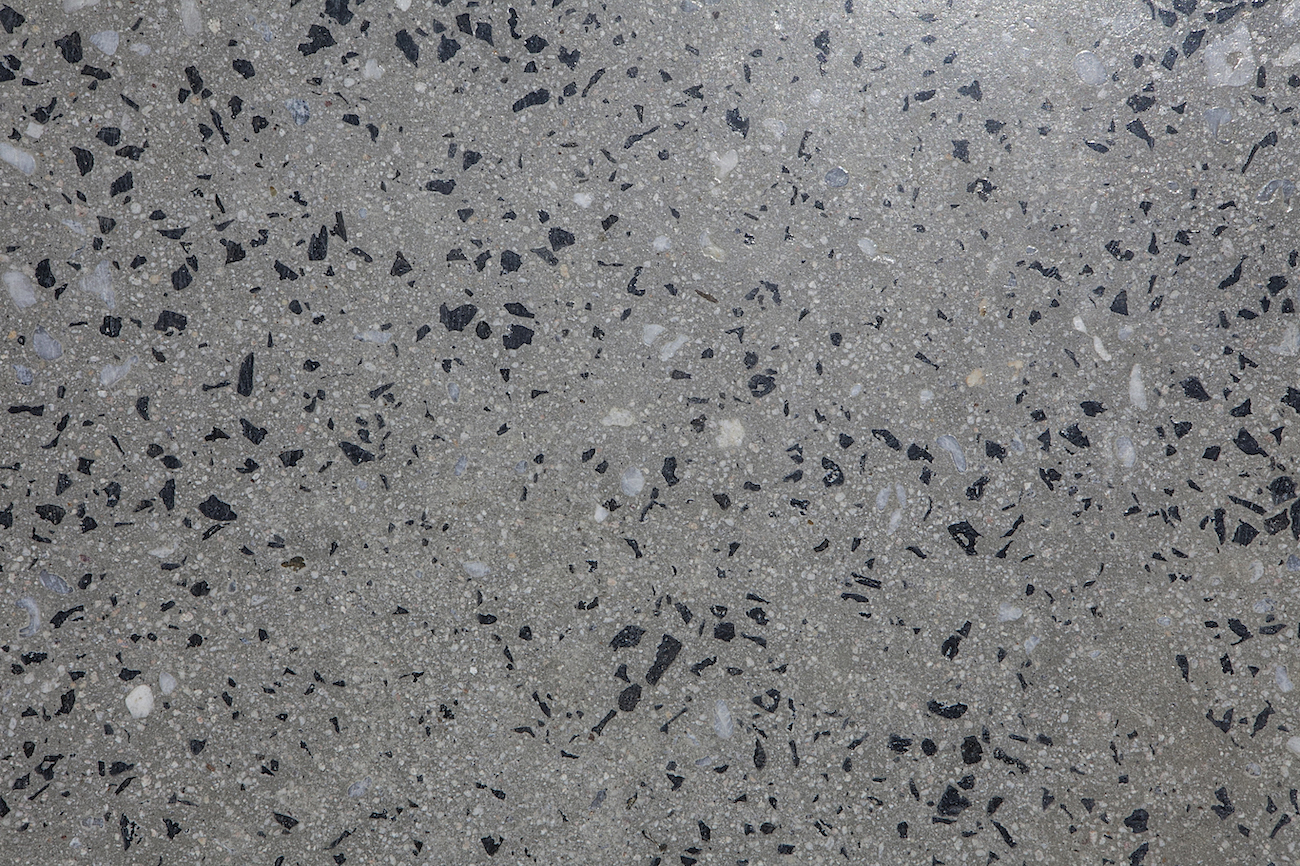

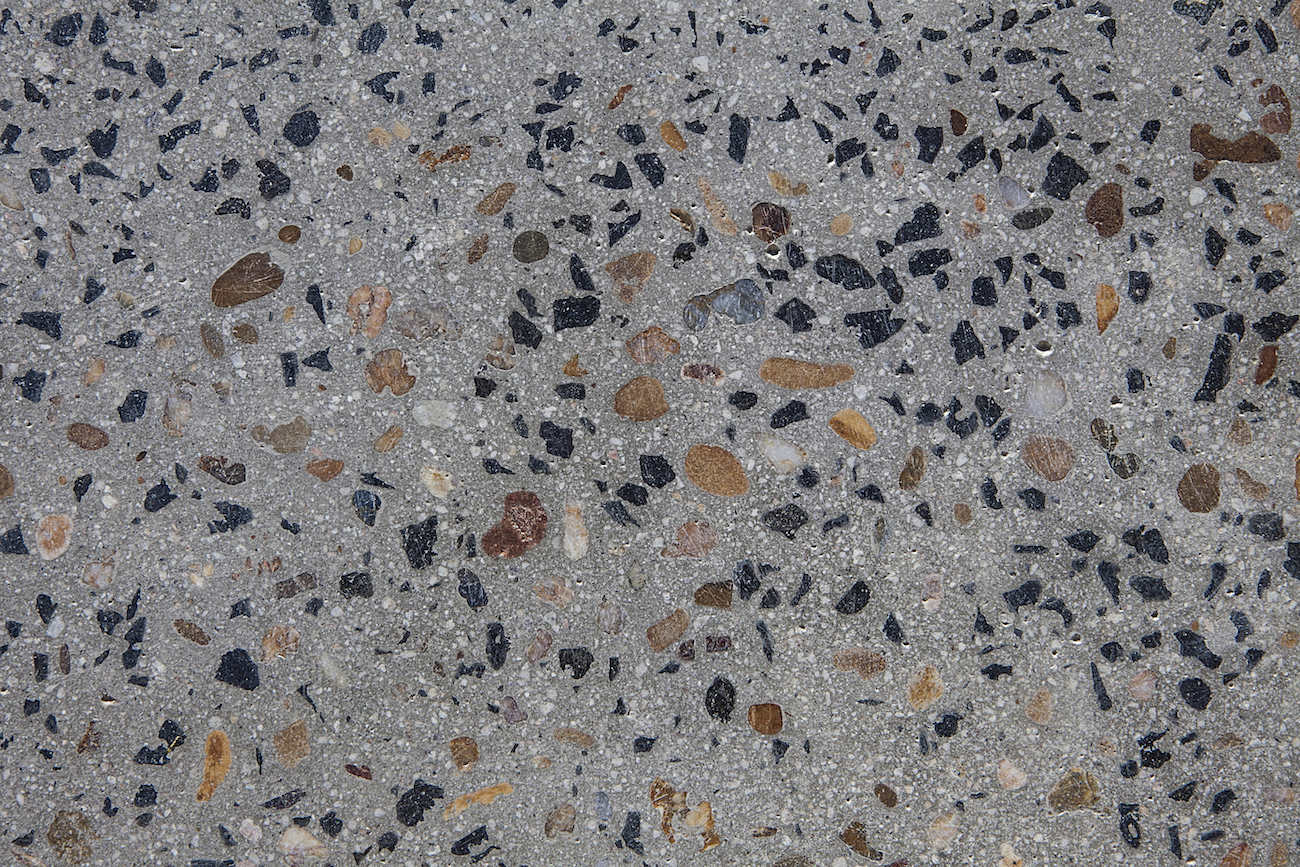

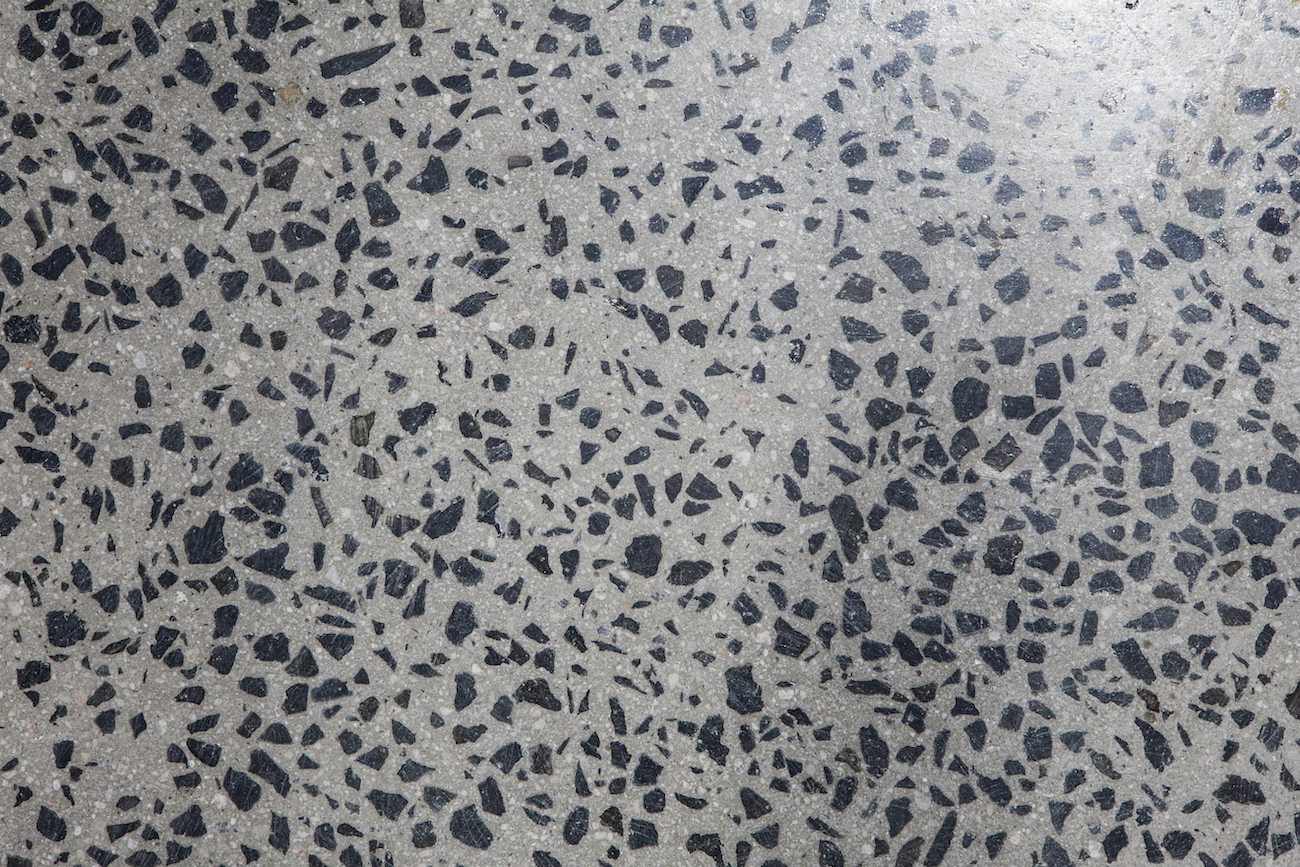

For new slabs you’ll need to choose your preferred aggregate (stone) and concrete colour. For new and old slabs you’ll need to consider the extent to which you want the slab cut – this is often referred to as the exposure of the aggregate and means how much of the stone you want to see, i.e. no stone exposure (‘nude’), a little exposure (soft grind/ ‘salt & pepper’), or medium exposure and full exposure where increasingly more of the stone is visible from grinding the floor surface.

The next choice involves the finished look of your polished floor – high gloss, low gloss or matt. If your floor is in a wet area (e.g. verandah, pool area or laundry) a nonslip finish is also available.

Below you’ll find some information on:

- choosing aggregates;

- choosing floor finishes;

- how to personalise your polished concrete floor;

- our polishing process;

- suggested maintenance; and

- the products we use.

Please contact us if you have any questions.